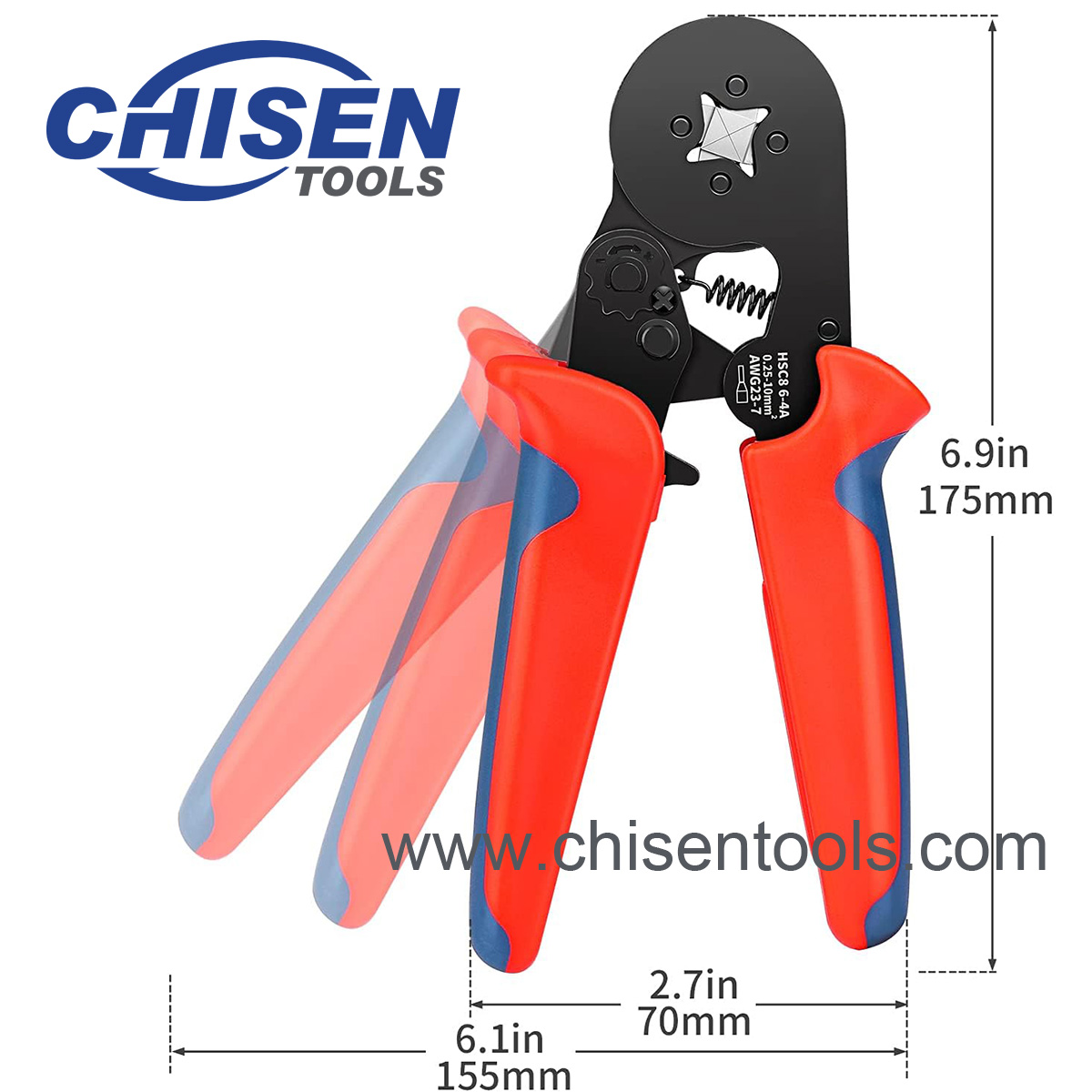

Self-adjusting Square Wire Crimper

Made of steel by special hardened,High hardness, Special four-mandrel crimping style for square crimp, It is ideal for crimping insulated and non-insulated wire ferrules,making ferrule crimp tool have good crimp performance.

Self-adjusting Square Wire Crimper for Wire Ferrules

Item No.:CS07003

Length:7" (195mm)

Material: Carbon Steel

Surface Fishing: Blacked

Handles: TPR+PP Ergonomic Handles

Capacity: 0.25~10mm2 | AWG: 23~7

Features:

Self-Adjustable Ratchet: Featured with a star wheel for adjusting crimping pressure to deliver precise crimping and effectively prevents the ferrules from being over crimped. If the ferrule is not tightened, you can adjust the ratchet pressure.

Safety Lock & Quick Release: Handle can be locked by squeezing the handle when not in use and store in carry bag. A release trigger inside the handle, push up when locking and quickly open the jaws.

2-Color Nylon & TPE Handle: Ergonomic design, providing non-slip grip and comfortable hand feel. lightweight and labor-saving, reducing hand fatigue. More efficient, operating with less effort.

Applications: Supports industrial electricians, hobbyists of connection, or DIYer 'to quickly make reliable connections in any screw terminal projects, equipment switch, relay power supply, car audio, lamp, speaker wiring project.

Wire Ferrule Crimping Tool

When terminating stranded wire, you need a reliable tool to crimp ferrules on the wire ends. Find out in this article the best wire ferrule crimping pliers you can use for your small and big electrical projects.

Stranded electrical wires are more flexible and easier to bend and manipulate than solid-core conductors. They are less likely to break than solid core when you subject them to frequent flexing. This is one of the reasons they are common in electrical equipment and installations where space is limited and wires have to be bent to fit. Stranded wires also offer superior resistance to vibration, which is why they are common in automotive wiring.

Unfortunately, flexible wires can be problematic if the wire strands are not managed properly. Exposed wire strands after stripping the insulation can be a safety concern. This is why wire ferrule crimps and ferrule crimping pliers are necessary when dealing with stranded wires.

Why Are Stranded Wires a Problem?

If you do not manage the strands of a flexible cable properly after stripping it, you could be shooting yourself in the foot. The loose wire strands can get into the wrong places in your circuitry and short things up.

Sometimes if you are connecting the stranded wire to a screw terminal, the screw could split the strands apart. This can cause some strands not to be used effectively, which can result in a poor electrical connection.

A poor connection can easily become a high resistance point in your circuitry, especially for high currents. And with high electrical resistance, comes high electrical losses because of heating. If the connection point overheats, it could burn or deteriorate the circuit board and the nearby electronic components. Sometimes a loose electrical connection can cause a fire.

Frayed wire strands are also a potential safety hazard. They can either prick your skin or expose you to electrical shock.

How to Manage Bare Stranded Wire-ends

Whether you are wiring up an industrial machine or a power supply for your hobby project or connecting a flexible wire cable to a block terminal or circuit breaker, you need to find a way to manage the bare wire strands.

There are 3 ways to manage bare stranded wire-ends. One way is by twisting the strands together and soldering them. Another way is to terminate the wire strands with a regular wire terminal crimp. The third and the most reliable way is to crimp a wire ferrule over the bare stranded wire end to securely hold all the individual strands together.

In this article, I look at ferrule crimping and more importantly, the best ferrule crimper pliers for securing ferrule sleeves.

What is a Wire Ferrule?

A wire ferrule is a thin metal tube for terminating the ends of a stripped stranded wire. It holds the strands together to keep them nice and neat. Unlike regular crimp connectors, ferrules do not provide different connector configurations. They are only metal sleeves for managing the stripped ends of flexible cable to keep the strands from fraying out when inserted into terminals.

A wire ferrule is easy to install. You just slide it over the stripped wire end and compress it with a ferrule crimper. While you can regular crimpers or pliers to compress the ferrule, the outcome is not that great.

The best tool for installing wire ferrules is a wire ferrule crimper tool. This is a special type of pliers designed for compressing ferrules to secure the strands of a stripped flex cable. You can learn more about ferrule crimpers and how to install them in this article.

How to Choose the Best Ferrule Crimper Pliers

There are many types of wire ferrule crimping tools and choosing the best one can be an uphill task. But this buying guide should help you pick the tool that will bring the most value.

So, what factors shou you consider?

1. Crimp profile

Ferrule crimpers have different crimp profiles. The best are either square or hexagonal profiles.

A square profile ferrule crimper compresses a ferrule sleeve to form a four-sided terminal. On the other hand, hex profile ferrule crimping pliers deform a round ferrule sleeve into a six-sided terminal.

Both of these crimp profiles create a firm terminal but are suitable for different applications. A square profile crimp fits better in rectangular-shaped terminal connections while hex profile crimps fit better into round shape terminal blocks.

That being said, hex crimped ferrules have a slight advantage over other crimp profiles when dealing with small ferrule sleeves. From experience, the extra crimping points of a hex ferrule crimper result in a significantly firmer crimp.

You can tell the type of profile on a ferrule crimping tool by counting the number of teeth on the zigzag crimper. Hexagonal ferrule crimping pliers have 6 teeth while square ferrule crimpers have 4 teeth.

2. Ratcheting or non-ratcheting crimping action

Cable ferrule crimping pliers operate either through a ratcheting or non-ratcheting action. The best ferrule crimpers are those that utilize a ratchet mechanism to compress the crimps.

The ratcheting action ensures you apply less force on the handle to achieve the same or better crimping quality than you would with a non-ratcheting crimper.

In fact, because ferrule crimpers with a ratcheting action require less hand strength, they are called labor-saving crimpers. They are so easy to use even for teens and the elderly.

3. Crimp capacity

Another important consideration when shopping for a wire ferrule crimper is the crimp capacity. This is the range of wire gauges the crimping pliers can accept.

Unless you work with specific wire gauges, I suggest you select a ferrule crimper that can press ferrules on general wire sizes. Ideally, a crimping range of 10AWG to 20AWG should suffice.

However, if you want to be sure that the crimper can work with specific wire sizes, I would advise that you check the size of the wire cable first. You will find wire size imprinted on the cable jacket or insulation. That way, you will be sure that the crimper isn’t too big or too small for your application.

4. Extra Accessories

Wire ferrule crimping pliers come either as a bare tool or as a kit. The kit includes an assortment of different sizes of ferrules. Some ferrule crimping tool kits even include a compartmentalized carry case for both the tool and the collection of ferrule crimps.

You will also find multi tool crimping pliers that come with a range of interchangeable die sets for crimping various types of bootlace ferrules and regular crimp connectors.

I recommend that you get the kit instead of the bare tool, especially if you are just getting started with ferrules. It will save you from the hassle of having to buy the wire ferrule sleeves separately.

But if you already have enough ferrules for your project, you can save some money by spending on the tool alone.

5. Overall build

Like any type of pliers, a good wire ferrule crimping pliers tool should be easy-to-use, light, and comfortable in your hands. As such, you should look for features such as comfort-grip handles, the weight of the tool, and of course labor-saving mechanisms such as the ratcheting action.

How To Crimp Wire Ferrule With And Without Ferrule Crimping Tool

A good way to fix bad electrical connections in your wiring is to terminate the stripped ends of flexible wire with ferrule crimps. Read this article to learn how to do it with or without cable ferrule crimping pliers.

The best tool for crimping ferrule sleeves is definitely a ferrule crimper. But when you don’t have this special tool at hand and you want to terminate a stripped stranded electrical wire, you can use pliers.

However, it is good to mention that you will not get the same quality of crimp with regular pliers as you would with a good ferrule crimping tool. But the outcome is far much better than inserting bare wire strands directly into the connector, nonetheless.

What is a wire ferrule?

A wire ferrule is a type of metal sleeve (mainly tin-plated copper) for capping the end of a stranded electrical wire. It keeps the sire strands of flex cable from fraying or sepercating after stripping the insulation.

Once crimped in place, the ferrule tube binds the fine electrical wire strands together to make one solid core. In other words, a ferrule crimp gives stranded wire the quality of solid wire at the connection point. This ensures that you get a quality electrical connections at the electrical terminals.

Benefits of using wrie ferrules

As you probably know, flex cables are the number one choice for most electrical applications. Unfortunately, they make the least reliable electrical connection when the bare wire strands are connected directly.

The free strands are difficult to manage and can easily corrode with atmospheric elements to increase resistance. This together with other factors is why you should terminate stranded wire ends with ferrule bootlace terminals.

Wire ferrules or bootlace terminals help manage the loose wire strands of stripped flex cable. They secure all the strands together to provide maximum electrical contact on screw terminals and breakers. This helps improve electrical safety when working with flex cables and reduces the risk of panel failure due to overheating and short circuit incidents from loose wire strands.

Other advantages of terminating stranded wire with ferrule crimp connectors are that ferrules simplify electrical installation work and make the work look neat.

Ferrules vs Standard Crimp Connectors

Wire ferrules and wire crimp connectors do the same job of terminating electrical wire. But they differ mainly in how the crimping takes place.

Ferrules are crimped over the bare wire strands while crimp connectors are crimped on the bare wire and onto the insulation after the stripped end.

Another difference is that a ferrule crimp acts as a cap for wrapping the stripped stranded wire whereas a standard crimp terminal serves as a metal extension to a stripped wire end offering different configurations.

Some of the common types of regular crimp terminals include the spade (male and female), ring, and butt splice connector types. An example of a regular crimp connector is the terminal lug you find on battery posts or the grounding wire connecting to the chassis on most appliances.

How Do You Crimp Ferrules?

As I mentioned, the best way to crimp ferrule connectors is by using a ferrule crimping tool. This special crimping tool compresses the ferrule tube over the wire strands to keep them intact and eliminate any wiggle that may affect the integrity of the electrical connection.

But when you do not have ferrule crimping pliers at hand, you can try to use regular wire crimpers or any pliers with a crimping feature. However, the results with these alternative tools are not the same as when you use a proper crimping tool for ferrules.

Regular pliers and crimpers do not create a proper cold weld as does a ferrule crimper. But they are better than nothing.

In the next sections, I will share how to install ferrules with ferrule crimping pliers as well as other types of pliers you can use to squeeze ferrules in tricky situations.

How to crimp wire ferrule with ferrule crimping pliers

This is a step by step guide for crimping a ferrule cap with ferrule crimping pliers. But before you start installing ferrules, make sure the wire is not live. You should never install ferrules on live wires!

Step 1: Identify the size of wire you want to crimp.

The size of the wire will help determine what size of ferrule you need. Typically, a ferrule should be the same size as the wire.

Step 2: Select the right size ferrule connector.

Use the size of the flex wire you want to terminate to determine the correct size of ferrule crimp. As mentioned above, the size of ferrule should be the same as the size of the cable. For instance, use a 6 AWG ferrule for a 6 AWG cable. If you have a bunch of wire ferrules and don’t know their sizes, select the smallest ferrule diameter that best fits the wire.

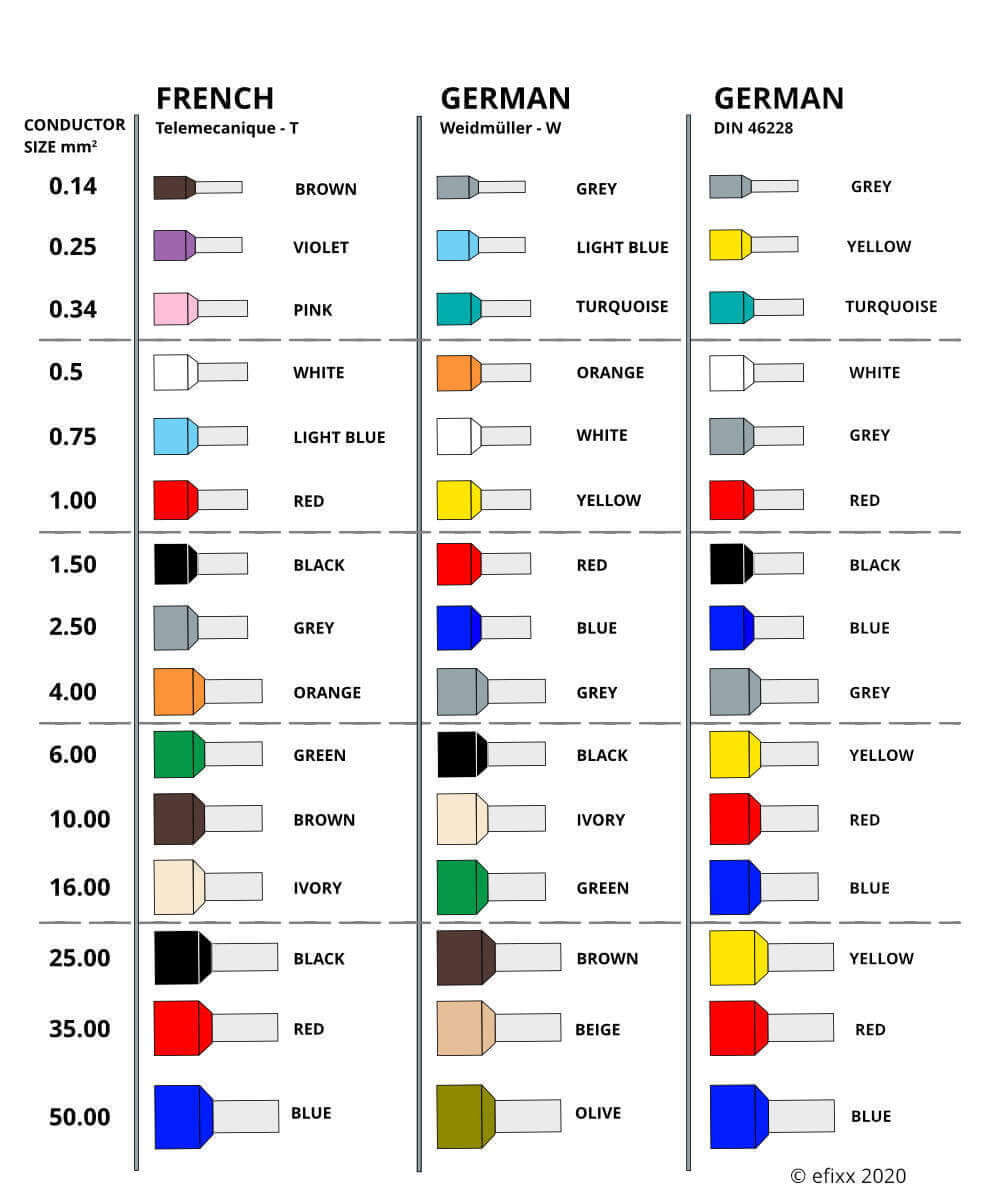

Alternatively, If you are working with insulated ferrules, you can use the ferrule color code chart below. It has all the French and German color codes for ferrules.

Step 3: Strip the wire to the proper length.

The stripped end should be long enough to fit in the ferrule tube. The stripped end should be about 1 cm. But to avoid making mistakes, just measure the length of the ferrule tube and strip away the same length of wire insulation.

Step 4: Insert the stripped wire end into the ferrule terminal.

Give the free strands a slight gentle twist before putting them through the sleeve. The bell-type entry of the ferrule will guide the stranded wire nicely all the way to the insulation so that no conductor is visible.

Make sure the tip of the wire touches the bottom of the tube. If the stripped section is shorter, remove more insulation from the wire with a wire stripper. If the section is longer, cut it to length with a pair of diagonal pliers or ordinary wire cutters.

Step 5: Crimp the ferrule assembly with your crimping tool.

Simply insert the ferrule terminal assembly inside the jaw of the crimping tool and squeeze the handles firmly to crimp. Squeeze them all the way to tightly secure the wire into the ferrule connector.

Step 6: Test the quality of the crimp.

Do a pull or tug test on the crimp to make sure it is tight and will not come off. Pull the crimped part and the rest of the wire in opposite directions.

If the crimped ferrule comes off or if you notice any wiggling, repeat the last two steps. Otherwise, your wire is properly crimped and ready to make a quality electrical connection.

- Combination Pliers

- Long Nose Pliers

- Diagonal Cutting Pliers

- Bent Nose Pliers

- Round Nose Pliers

- End Cutting Pliers

- Wire Stripper

- Mini Pliers

- Circlip Pliers

- Slip Joint Pliers

- Groove Joint Pliers

- Tower Pincers

- Locking Grip Pliers

- Fishing Pliers

- Wood Chisel

- Adjustable Wrench

- Combination Spanner

- Double Open End Spanner

- Double Offset Ring Spanner

- Hammer

- Axe

- Screwdriver

- Bit

- Bolt Cutter

- Pipe Wrench

- Aviation Snip

- Tin Snip

- Pruning Shear

- Pipe Cutter

- Cable Cutter

- Glass Cutter

- Hair Scissors

- Pet Scissors

- Kitchen Scissors

- Utility Knife

- Electrician Knife

- Saw

- New Universal Socket Wrench

- F Clamp for Wood Working

- Wood Turning Lathe

- Hydraulic Gear Puller

- Hydraulic Cable Lug Crimper

- Hydraulic Cable Cutter