What is Teflon Coating?

Teflon is actually the brand name that commercializes this product, but the coating itself is called Polytetrafluoroethylene or PTFE. There are mainly two types of PTFE coatings such as one-coat PTFE and two-coat PTFE that consists of a primer and a topcoat. They are used in various applications because of their impressive list of advantages.

Telflon Coating's Physical Properties

| Density [g/cm3]: | 2.07 |

| Hardness [Shore D]: | 57 |

| Friction Coefficient [Steel]: | 0.0646 |

| Water Absorption [%]: | 0.0074 |

| Melting Temperature [°C]: | 325 |

Detailed Description:

Teflon® (Polytetrafluoroethylene): Definition, Properties, Types, and Applications

Teflon®, also known as PTFE (polytetrafluoroethylene) is a fluoropolymer that consists of carbon and fluorine atoms. The fluorine atoms protect the carbon backbone and give it excellent mechanical, thermal, and electric properties. Teflon® is used across all industries in several applications including: wire coatings, low-friction coatings, bearings, chemical tank liners, and cookware (Figure 1 below).This article will describe what Teflon is, who invented it, its advantages and disadvantages, as well as its mechanical, thermal, optical, and electrical properties.

What is Teflon?

Teflon is a thermoplastic fluoropolymer whose chemical name is PTFE (polytetrafluoroethylene). Teflon is a trademark of Chemours, however, PTFE can also be purchased from companies other than Chemours. Teflon is a popular material due to its low friction and thermal and chemical resistance.What Is the History of Teflon?

Teflon was discovered by accident by Roy J. Plunket in 1938 while working for DuPont. It was discovered while Plunket was producing tetrafluoroethylene gas for testing a new type of refrigerant to potentially replace ammonia and sulfur dioxide. However, after cooling the tanks to -78.5 °C, the gas turned into a white powder. Plunket decided to characterize the material to determine its physical properties, leading to the discovery of Teflon. Teflon was made into a commercial product in 1946.What Is the Other Term for Teflon?

Teflon is a trademark of Chemours, however, the chemical name for Teflon is PTFE which stands for polytetrafluoroethylene. Rulon® is also a branded PTFE formulation.What Is Teflon Made Of?

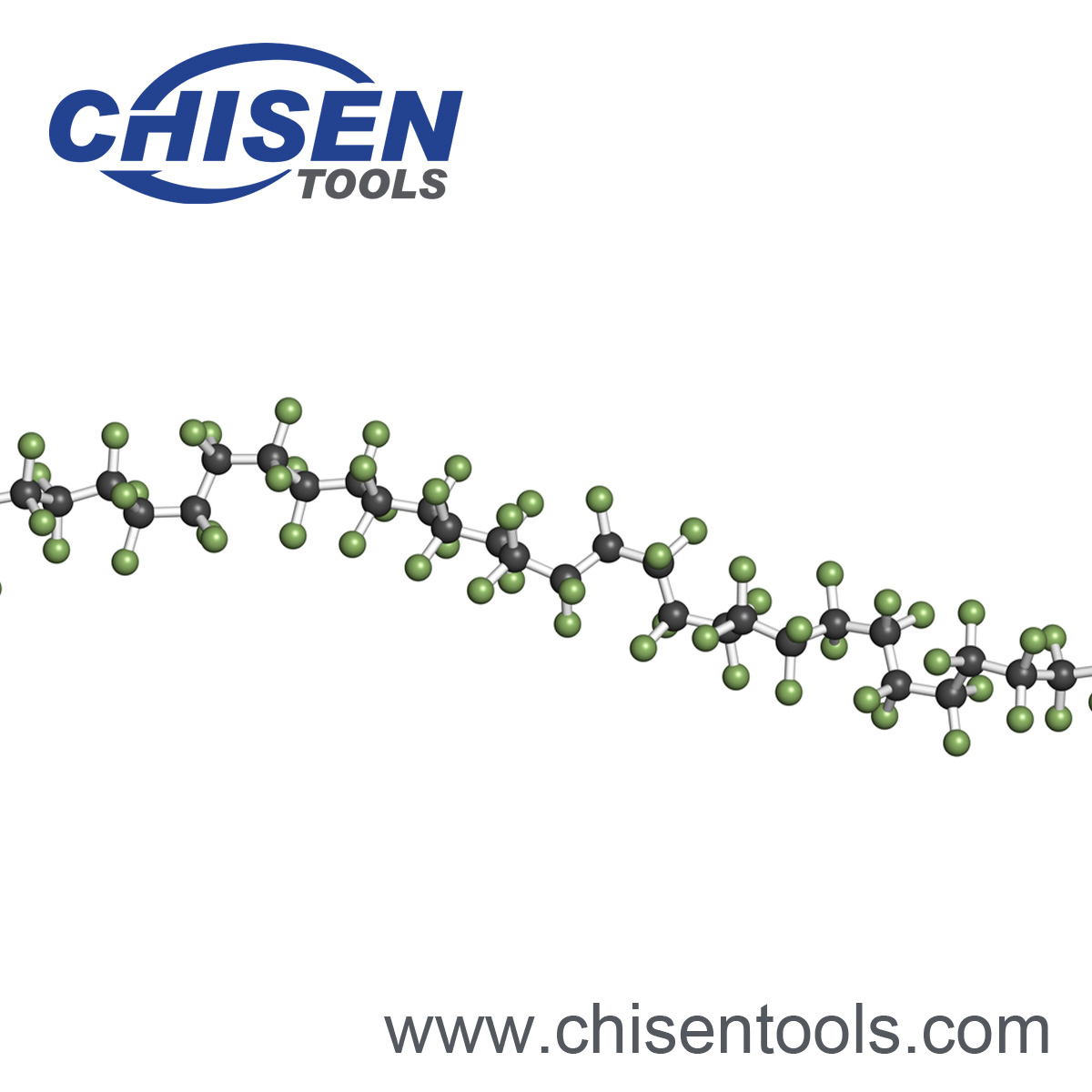

Teflon, whose chemical name is PTFE (polytetrafluorethylene) is a synthetic fluoropolymer with a helical linear structure. The chemical inertness of PTFE comes from the densely packed fluorine atoms that surround the carbon atoms, providing a protective layer. The picture below shows the carbon atoms in black and the surrounding fluorine atoms in green:

What Are the Properties of Teflon?

Teflon is most commonly used for high-temperature, corrosive environments. It also has one of the lowest coefficients of friction. Teflon is not often used for applications in which mechanical strength is required, however, its properties can be maintained at a much higher temperature when compared to most other polymers. Table 1 lists some physical properties of Teflon:Table 1: Physical Properties

| Density [g/cm3]: | 2.07 |

| Hardness [Shore D]: | 57 |

| Friction Coefficient [Steel]: | 0.0646 |

| Water Absorption [%]: | 0.0074 |

| Melting Temperature [°C]: | 325 |

What Are the Mechanical Properties of Teflon?

Listed below in Table 2 are some common mechanical properties of Teflon:

Table 2: Mechanical Properties

| Ultimate Tensile Strength [MPa] | 35 |

| Yield Strength [MPa] | 20.5 |

| Elongation at Break [%] | 306 |

| Flexural Yield Strength [MPa] | 19.6 |

| Flexural Modulus [GPa] | 0.672 |

| Compressive Yield Strength [MPa] | 10.2 |

| Charpy Impact Strength [J/cm2] | 1.76 |

What Are the Chemical Properties of Teflon?

Teflon is resistant to a wide range of chemicals including: acids, bases, solvents, hydrocarbons, oils, fuel, water, and alcohol. It is one of the most chemically resistant materials available. However, Teflon can be damaged by alkali metals, gaseous fluorine, chlorine trifluoride, and oxygen difluoride.

What Are the Optical Properties of Teflon?

Teflon AF is an amorphous version of Teflon that is able to achieve high levels of optical clarity (> 95% transmission), a low refractive index (1.31), as well as excellent UV (ultraviolet) stability. This is achieved while maintaining Teflon's excellent thermal and chemical resistance.

What Are the Electrical Properties of Teflon?

Listed below in Table 3 are some common electrical properties of Teflon:

Table 3: Electrical Properties

| Electrical Resistivity [Ω.cm] | 8.68E+17 | Surface Resistance [Ω] | 4.48E+17 | Dielectric Constant | 2.39 | Dielectric Strength [kV/mm] | 58.7 | Dielectric Loss Index | 0.0001 | Arc Resistance [sec] | 346 |

What Are the Types of Teflon?

Teflon/PTFE can be produced in a number of different forms for use in different applications. Some common Teflon variants are discussed below:

1. Granular PTFE

Granular PTFE is synthesized via suspension polymerization. This material is typically used to make stock shapes like rods or tubes. It is processed using one of two techniques, namely isostatic molding (pressure applied in all directions) and compression molding (pressure applied in one direction). These compressed forms must then be sintered.

2. Fine Powder PTFE

Fine powder PTFE is synthesized using a technique called emulsion polymerization. The powder is often mixed with solvents that give it a paste-like consistency. This paste can then be extruded to produce films, wire, tubing, and fibers using a technique called paste extrusion. After extrusion, the paste must be dried and sintered. This grade of PTFE powder is often called emulsion grade.

3. Micro Powder PTFE

Micro PTFE powder is synthesized using a technique called direct polymerization, other techniques such as milling and grinding are also possible. It is typically used to decrease friction between contacting surfaces and as an additive for other polymers to improve lubricity, wear resistance, and flame resistance. Micro PTFE particle sizes are typically between 1–20 µm.

4. Dispersion PTFE

Dispersion PTFE is essentially PTFE particles dispersed within a fluid. This form of PTFE is used for impregnating industrial fabrics while also being used for coatings on cookware for example. Dispersion PTFE is able to augment materials and surfaces with the properties of PTFE such as chemical resistance, low friction, and heat resistance.

5. Film PTFE

PTFE is often formed into films that are used for applications like low-friction pipe sealing tape. It is commonly produced by a process called skiving in which a thin film is shaved off of a round bar of solid PTFE. Thicknesses of as much as 0.5 mm are possible. Films as thin as 0.05 mm are possible by making use of an extrusion process. These films can be etched on one side to aid in adhesion to other materials.

6. Expanded PTFE

Expanded PTFE is most commonly used for gaskets as it has excellent thermal and chemical resistance, as well as being compressible so that it can account for any irregularities on a flange face. Expanded PTFE consists of many microscopic fibers that give it a flexible and elastic structure.

What Are the Applications of Teflon?

Teflon has many beneficial properties that make it useful in a large range of applications, some of which are listed below:

1. Bearings & Seals

Teflon is commonly used on bearings and low-friction bushings due to its: low friction, thermal resistance, and corrosion resistance. Teflon is also used as a sealing material in threaded pipe connections as well as a gasket material in piping connections.

2. Electrets

An electret is a dielectric material that retains its electric charge after being exposed to a strong electric field. Electrets are often used in a wide range of applications such as sensors, vibration pickups, and filters. Teflon is ideal for an electret as it can retain its charge for long periods and have low dielectric losses.

3. Chemically Inert Liners

Teflon is resistant to a wide range of corrosive chemicals. It is an excellent material for liners for chemical storage tanks and pipes. Teflon is only damaged by molten alkali metals and fluorinating compounds.

4. Tensioned Membrane Structures

A tensioned membrane structure is similar to a tent, however, the fabric is put under extreme tension to improve rigidity. Teflon is often used as a coating for woven fiberglass membranes. The Teflon coating is highly resistant to UV (ultraviolet) radiation as well as being hydrophobic and temperature resistant.

5. Composites

Teflon films are used in the manufacture of composites. For example, when removing air from a composite form, a Teflon film is used so that bonding resin does not stick to various items of processing equipment, including during any necessary heat-treatment stages. This is possible due to Teflon’s high thermal resistance.

6. Musical Instruments

Teflon can be used to coat the strings of a guitar for example. This reduces the friction between string and finger as well as preventing corrosion and improving wear life. PTFE-containing lubricants are also used in some wind instruments to lubricate the moving components.

7. Lubricants

Teflon can be made into a micro powder that can behave as a lubricant if mixed in with an evaporating solvent. This allows the micro powder to penetrate between surfaces to lubricate their contacting surfaces.

8. Kitchenware

One of the most commonly recognized uses of Teflon is as a cookware coating on pots and pans. These coatings can withstand the high temperature of cooking and prevent any food from sticking to the cookware.

9. Medical Applications

Teflon does not react with biological tissue. It can be used in vivo without the risk of the body rejecting it. Other applications can include medical tubing, pumps, and catheters. Teflon-coated catheters were shown to have increased infection resistance. PTFE is also antistatic and helps prevent the build-up of foreign objects on medical tools like scalpels.

10. Automotive Applications

Teflon is widely used in the automotive industry due to its thermal and corrosion resistance. Typical examples can include fuel lines, head gaskets, wire coatings, and various seals and bushings. Teflon is also used as a coating to reduce the wear between mechanical components.

11. Aerospace Applications

The aerospace industry often requires advanced materials to withstand the extreme conditions that aircraft and spacecraft are exposed to. Teflon wire coatings are used on spacecraft and rovers due to their excellent thermal and UV resistance. Other applications can include gaskets, fuel lines, bearings, and fasteners. Teflon is also used as a coating to reduce the wear between mechanical components.

12. Wire Insulation, Electronics

Teflon is an excellent insulator and is flexible which means it will not permanently deform when rolled or bent during installation or operation. These properties make Teflon an excellent insulator for electric wiring. Teflon also has low dielectric losses which makes it ideal for sensitive applications such as antennas.

Is It Safe To Use Products With Teflon?

PTFE is chemically inert and is often used for coating cooking surfaces. It is safe to be used in contact with food. However, if overheated, the fumes from Teflon-coated cookware can cause a flu-like sickness called polymer fume fever.

What Are the Advantages of Teflon?

Some common Teflon advantages are described in detail below.

- Thermal Resistance: Teflon has a melting temperature of 325 °C and can maintain its properties down to -275 °C.

- Low Friction: Teflon has one of the lowest friction coefficients of any material. It can be used to reduce friction between surfaces in its solid form as well as used as an additive to reduce friction in other polymers.

- Chemically Inert: Teflon is chemically inert and is resistant to the vast majority of chemicals. However, some chemicals can still destroy PTFE.

What Are the Disadvantages of Teflon?

Some common Teflon disadvantages are described in detail below:

- Non Stick: While its non-stick properties make Teflon an excellent coating for cookware, this same property makes it very difficult to bond Teflon to other surfaces.

- High Thermal Expansion: Teflon has a very high thermal expansion that is larger than most other plastics.

- Poor Radiation Resistance: Teflon cannot withstand high-energy radiation and will break down when exposed.

FAQs

Is Teflon Biodegradable?

No, Teflon is not biodegradable and will not break down under natural conditions as it has high thermal, chemical, and UV (ultraviolet) resistance. Teflon can, however, be recycled.

Is Teflon Water Soluble?

No, Teflon is resistant to moisture ingress and will not dissolve in water.

Is Teflon Elastic?

Yes, however, this is only true at low elongations.

Is Teflon a Type of Polymer?

Yes, Teflon is a fluoropolymer. Its molecular chain consists of a carbon backbone with tightly packed fluorine atoms around it.

What Are the Differences Between Teflon and Plastic?

Teflon is a type of plastic, specifically, it is a thermoplastic polymer.

What Are the Differences Between Teflon and Metal?

Teflon is a polymer made up of repeating carbon and fluorine molecules. Metal typically has a crystalline structure and is made up of tightly placed metallic elements like iron and aluminum for example.

What Are the Differences Between Teflon and Silicone?

Both silicone and Teflon are polymers with high thermal resistance. However, silicone has a relatively high friction coefficient compared to Teflon and is also a thermosetting polymer compared to Teflon—a thermoplastic polymer.

What Are the Differences Between Teflon and Nylon?

Teflon and nylon are both thermoplastic polymers. Nylon has a relatively low friction coefficient compared to most other polymers but is still higher than Teflon. Nylon also has a lower thermal and chemical resistance when compared to Teflon. However, nylon is easier to process.