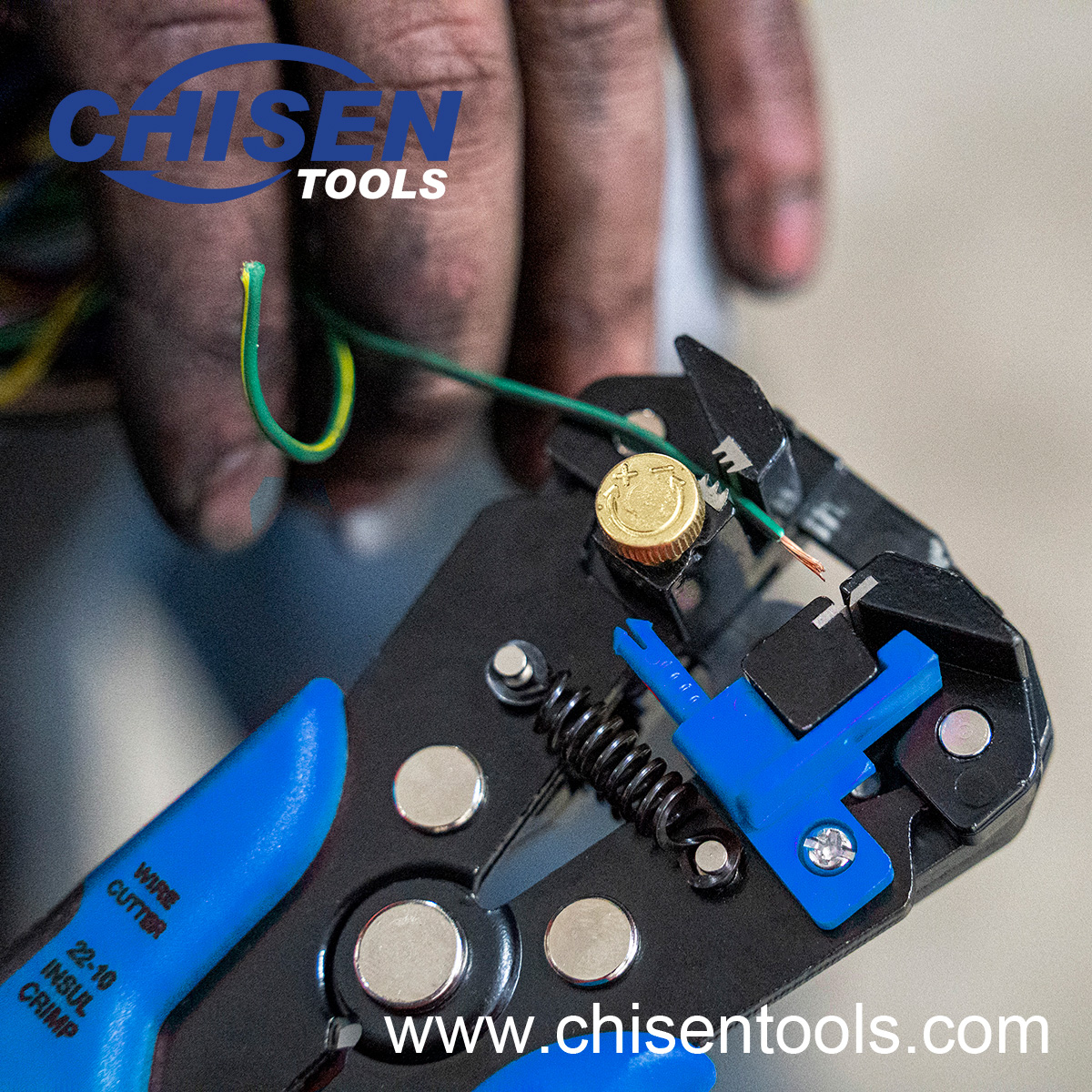

Self-adjusting Wire Stripper

Slef-adjusting Wire Stripper, Ajustable Automatic Wire Stipper,

Self-adjusting Wire Stripper

Item No.:CS07002

Length:8" (206mm)

Weight: 331g (12.7 ounces)

Material: Chrome-vanadium Steel, Cr12MoV

Surface Fishing: Blacked & Precision Polishing

Handles: PVC Ergonomic Handles

Features:

1. Made by high-quality chromium-vanadium alloy steel, which has high hardness, good toughness and durability; the main body is made of high-quality tool steel, which is convenient for cutting and precise crimping

2. Bat-shaped fixture design, the grip is more stable, and the stripping is not easy to slip

3. The stripping adjustment button is designed to adjust the tightness of the bite force according to the size of the thread, which is convenient and quick to use

4. Handle: PP+TPR two-color encapsulation, which is comfortable to grip and ergonomic, suitable for long-term use

5. Hardness:HRC55-60

Wire stripper for quickly and easily removing the protective coating from electrical wires; ideal for DIYers and professional electricians

Self adjusting: can strip 10 to 24 AWG wire; crimps 10-22 AWG insulated/non-insulated wire and 7-9mm ignition terminals

Made of durable corrosion-resistant alloy steel; secure-grip handles for comfort and control

2-inch jaw width; built-in adjustable stopper for controlling the length of the core strip

Capacities

| Function | Capacity |

|---|---|

| Stripping | 24~10AWG / 0.2~6mm² |

| Crimping (Insulated Terminals) | 22~10AWG/0.5~6mm² |

| Crimping (Non-insulated Terminals) | 12~10AWG/4~6mm², 16~14AWG/1.5~2.5mm², 22~~18AWG/0.5~1mm² |

| Cutting | 24~10 AWG / 0.2~6mm² |

How to Use Self-adjusting Wrie Stripper?

If you work on a lot of electrical projects, you should have a good wire stripper stocked in your tool bag. Wire strippers look similar to pliers and are used to remove the protective coating material from wires—something you need to do a lot when repairing wires, setting up speakers, or working on electrical projects. The best wire strippers can also cut wires and cables, crimp wiring, and cut screws.

Before deciding on which electric wire stripper you plan on buying, make sure to consider a few major factors like the type of stripper, the gauge sizes, and basic safety criteria.

Type

Gauged

Sometimes called a manual wire stripper, this type has different notches that correspond to common wire gauges, so you just need to select the correct hole to fit the wire you’re working on. Gauged wire strippers provide set spaces on the tool for a standardized strip every single time. The one downside of gauged strippers is the lack of size options.

Adjustable

Adjustable wire strippers have just one open notch to use, and can be widened or tightened based on your needs and the thickness of wire. This allows for accurate, precise stripping based on each individual wire. Most adjustable wire strippers have a tightening mechanism to ensure that the notch doesn’t widen or grow too tight when in use. Adjustable strippers do rely on your adjustments, however—which, if not precise, may damage the wires beneath the jacket.

Automatic

Also called a self-adjusting wire stripper, this tool automatically conforms to the needed size when you insert the wire. These strippers don’t require any measurements or gauges in order to function. The automatic stripper is only limited by the overall size range it covers.

Gauge Sizes

Wire size refers to a wire’s diameter, which is often measured according to the American Wire Gauge (AWG) measurement system. AWG sizes range from 0000 to 40. It can be confusing, because the thinner the wire, the larger the AWG number. Wire can be solid or stranded; the stranded wires have a larger diameter. The most common gauges of wire in residential settings are between 6 and 14 AWG, but you might be working with gauges outside of that range, depending on the jobs and setting involved. Make sure to select a wire stripper that can accommodate the wire sizes you’ll need, and keep in mind that wire strippers can have different gauge ranges for stripping, cutting, and crimping.

Safety Criteria

Look for VDE certification that indicates a wire stripper has met essential safety standards. The VDE Testing and Certification Institute tests and certifies electrical tools and equipment and is considered the global authority in this area. Typically, wire strippers will be VDE-certified and approved for up to 1,000 volts.

What Is a Wire Stripper?

Every professional electrician makes daily use of a common tool known as a wire stripper and most own several different forms of this tool. Every DIYer who does any kind of electrical repair should also own some version of a wire stripper. Especially useful is a version commonly known as a combination tool, which not only has a wire stripping function, but also pliers jaws, cable-cutting blades, and a couple of threaded holes for cutting bolts commonly used with electrical boxes.

A wire stripper is a hand tool designed to remove the protective covering, or jacket, from electrical wires. By removing the jacket, the wire stripper helps the electrician expose the wire for new uses or repairs.

Wire Stripper vs. Self-Stripping Tool

Another type of wire stripper is a self-stripping tool, or self-adjusting wire strippers, that removes wire insulation with a compound action. This means that three actions take place when you squeeze the handle: grip, strip, and remove. After you precisely place the wire in the head and squeeze the handle, the stripper grabs onto the wire, cuts the insulation, and completely removes it from the wire, all in one motion. Self-stripping wire strippers are more expensive than normal strippers. They serve one function only and are normally owned by professional electricians who prefer specialty tools for each function.

| Wire Stripper | Self-Stripping Tool |

|---|---|

| More affordable Requires careful placement |

More expensive Cuts and removes in one motion |

Wire Stripper vs. Combination Wire Stripper

Combination wire tools, or combination wire strippers, are multi-function tools that have sharp cutting jaws to cut non-metallic (NM) cables or to trim individual wires down to size. They may also have pliers jaws that can be used to bend wires. The same jaws may also be used to ream the inside of the metal conduit after it is cut, using the outsides of the jaws when they are in the closed position.

Most combination strippers also have two different holes for cutting machine bolts, usually 6-32 and 8-32 sizes. You thread a bolt into the hole to the desired depth, then squeeze the tool's handles to cut off the end of the bolt. When you twist the bolt out of the hole, the threads in the hole realign the threads on the cut end of the bolt.

| Wire Stripper | Combination Wire Stripper |

|---|---|

| Designed only for wires Offers guides for proper cutting length |

Can cut wires and bolts Can be used to bend wires |

Parts of a Wire Stripper

In whatever form the tool takes, a wire stripper has a series of labeled holes that match the common wire gauges, typically 10-gauge to 20-gauge. When you insert the wire into the proper hole and squeeze the tool's handles, it precisely severs through the plastic insulation layer without damaging the copper wire. The tool then removes the wire insulation, using one of two methods.

It's important to note that copper wire commonly comes in either solid or stranded forms. Stranded wire is slightly larger in diameter than solid wire of the same gauge. For this reason, wire strippers often have two sets of numbers indicating the stripper hole sizes. For example, the hole that is marked for 10-gauge solid wire is the same hole you use for 12-gauge stranded wire. Always make sure you're using the correct set of markings for the wire type you are cutting.

How to Use a Wire Stripper

Although different manufacturers offer different versions of the tool, the process for stripping wires is largely the same with each tool. This is the process for the standard or combination-style tool:

Step. 1: Determine the Wire Gauge and Type

Identify the gauge of the copper wire to be stripped. You can find this on the outermost sheathing that binds multiple wires together inside an NM cable (nonmetallic sheathed cable). With a number such as 12/2, for example, the first number is the wire gauge (in this case, 12). Also, note whether the wire is solid or stranded copper.

Step. 2: Match the Wire to the Tool

Match the wire gauge with the appropriately labeled hole on the wire stripper. This step is essential: If you choose a hole that is too big, the insulation will not be fully cut and you'll have a hard time stripping it; if you choose a hole that is too small, the wire may be nicked or even severed entirely.

Step. 3: Open the Wire Stripper and Seat the Wire

Open the wire stripper handles. "Seat" the wire into one side of the proper hole. Slowly press the handles together until they can go no farther. This action will cut through the insulation on the wire.

Step. 4: Twist the Tool (if Needed)

If the wire insulation does not fully cut, you may have to gently rotate the wire within the hole (or the wire stripper around the wire, whichever is easier). You do not have to rotate far: just a quarter turn in one direction and back.

Step. 5: Strip the Insulation

Pull the wire stripper towards the cut end of the wire to remove the insulation. The action is like pulling a sock off a foot. Some users find it easiest to push against the tool using the thumb on the hand that is gripping the wire, while the other hand holds the handles of the tool firmly shut.

- Combination Pliers

- Long Nose Pliers

- Diagonal Cutting Pliers

- Bent Nose Pliers

- Round Nose Pliers

- End Cutting Pliers

- Wire Stripper

- Mini Pliers

- Circlip Pliers

- Slip Joint Pliers

- Groove Joint Pliers

- Tower Pincers

- Locking Grip Pliers

- Fishing Pliers

- Wood Chisel

- Adjustable Wrench

- Combination Spanner

- Double Open End Spanner

- Double Offset Ring Spanner

- Hammer

- Axe

- Screwdriver

- Bit

- Bolt Cutter

- Pipe Wrench

- Aviation Snip

- Tin Snip

- Pruning Shear

- Pipe Cutter

- Cable Cutter

- Glass Cutter

- Hair Scissors

- Pet Scissors

- Kitchen Scissors

- Utility Knife

- Electrician Knife

- Saw

- New Universal Socket Wrench

- F Clamp for Wood Working

- Wood Turning Lathe

- Hydraulic Gear Puller

- Hydraulic Cable Lug Crimper

- Hydraulic Cable Cutter